MIBC

MIBC

FLOTATION FROTHER-FLORREA MIBC

Trade Name: Florrea MIBC

Shipping Name: FLORREA MIBC

Chemical Name: MIBC (Methyl Isobutyl Carbinol)

IUPAC name: 4-Methyl-2-pentanol

Other names: 4-Methylpentan-2-ol, Methyl isobutyl carbinol, MIBC, Isobutyl methyl carbinol, 2-Methyl-4-pentanol, 4-methylpentane-2-ol, 1,3-Dimethylbutanol, Methyl amyl alcohol,

Isobutyl methyl methanol

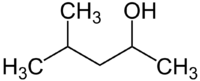

Chemical Structure:

Molecular formula :C6H14O

CAS number :108-11-2

EINECS No.: 210-790-0

ChemSpider :7622

ChEMBL : CHEMBL448896

Physical and chemical characteristics: Flotation frother Florrea MIBC -Methyl Isobutyl Carbinol is Colorless transparent liquid with characteristic odor . Methyl Isobutyl Carbinol is miscible with most ordinary organic solvent. Chemical properties of Methyl Isobutyl Carbinol is stable. It has high content of active ingredients.

Molar mass :102.174 g/mol

Melting point :−90 °C

Boiling point :131.6 °C

Solubility in water : 15 g/L ,Slight water-soluble

Solubility :soluble in ethanol , diethyl ether

Vapor pressure :0.698 kPa

Viscosity : 4.07 mPa·s

Flash point :41 °C

Autoignition temperature : 1 — 5.5%

Thermochemistry Std enthalpy of formation : ΔfHo298:-394.7 kJ·mol-1 (liquid)

Specific heat capacity , C: 273.0 J·mol-1·K-1 (liquid)

Specification

| Item |

Specification |

Analysis result |

|

RELATIVE DENSITY |

0.806-0.809 |

0.807 |

|

BOILING DEGREE |

128-133C |

130C |

|

Content of(CH3)2CHCH2CH(OH)CH3 |

≥99% Min |

99.3 |

|

water |

0.6% Max |

0.3% |

Application

4-Methyl-2-pentanol (IUPAC name) or methyl isobutyl carbinol (MIBC) is an organic chemical compound used primarily as a flotation frother for mineral flotation in mineral processing industry .

MIBC(Methyl Isobutyl Carbinol) is an excellent chemical mining reagent used as foaming reagent both for non-ferrous metal and non-metallic ores in mineral flotation process.

Methyl isobutyl carbinol (MIBC) is mainly used in the flotation plant of non-ferrous oxide ores or fine-grained sulfide ores containing a large quantity of soil grade

It is widely applied in flotation treatment of lead-zinc ore, copper- molybdenum, copper-gold ore and mineral processing of copper-gold ore . Methyl isobutyl carbinol (MIBC) has particular effect on improving the quality of concentrate and efficiency of mine recovery.

Methyl isobutyl carbinol (MIBC), an organic chemical compound, is a liquid derivative of acetone with a pungent alcohol odor. It has limited solubility in water, but is miscible with most organic solvents. The main uses of MIBC are as a frother in mineral flotation and in the production of lubricant oil additives.

Frothing, also known as froth flotation, is the process of selectively separating hydrophobic valuable minerals from hydrophilic waste gangue. In its simplest form, froth flotation is a method whereby minerals can be “skimmed” from the surface of “slurry” that is “foamed” with the assistance of specific chemicals, water and air bubbles.

MIBC is used as a frother in the flotation process in the mining of ores, such as copper and molybdenum sulfide, as well as coal. Compared to other frothers, Florrea’s MIBC product offers fast kinetics and excellent selectivity, and it forms dry but easy-to-break froths – increasing both the yield and the efficiency of mineral and metal recovery efforts. This technique results in an industry-leading way to separate valuable minerals from extracted ore.

MIBC can also be used in the production of lube oil additives (ZDDP) and for anti-wear and corrosion inhibitors – such as in the manufacture of brake fluid – and as a precursor to some plasticizers.

Florrea can provide full range of flotation frothers which is well-suited to enhancing frother performance. Florrea mining frothers is suitable for Mineral processing of base metal sulphides, precious metals (gold, silver, PGEs), industrial minerals, coal and various other non-sulphides.In developing 'frother' products our aim has been to improve flotation kinetics by influencing the induction time for solid/bubble contact. More rapid loading of hydrophobic particles into the froth phase is required in order to reduce gangue entrainment. Through the development of products that limit water recovery whilst maintaining froth mobility, we have been able show improvements in grade and/or recovery

IDENTIFYING FROTHING SOLUTIONS – MEASURING FROTHER PERFORMANCE

The decision to use a froth flotation process creates a range of options for a mine across collectors, modifier, and frothers. One significant choice for a mine using the froth flotation process is the selection of an optimal frother to generate quality froth and to maximize the recovery of minerals and metals from ore.

Frothers are neutral molecules that absorb at the water-air interface, aid in the production of bubbles for flotation, and stabilize the froth for collection and skimming.

Some examples of criteria that are used in the evaluation of frothers include –

-

Molecular Weight

-

Maximum Foam Volume – A higher value indicates a stronger foaming ability of the frother.

-

Foam Half-life – A longer half-life indicates greater foam stability.

-

Foam Comprehensive Index (FCI) – A calculation based on both the foam volume and the foam half-life measurements; the FCI attempts to create an objective measure across frothers.

-

Foam Rise Velocity – A ratio of foam height to aeration time; a larger velocity means a lower foam viscosity.

-

Foam Duration – The length of time that foam persists given a specific concentration level; the duration of a frother influences both recovery and the operation of the flotation cell.

Froth Surface Tension – The ability of a frother to break the surface tension of water.

Measuring the performance of frothers is an ongoing research initiative across universities, research centers, and within the mining industry. In the end, the true measure of a frother’s performance is in its ability to help a mine recovery a greater amount of metal or minerals. The importance of choosing the right frother can have a sizable financial impact, given its ability to affect the resulting recovery rate of the froth flotation process.

Packaging

| Item |

Packing |

Quantity |

|

1 |

UN approved Iron drum of 165KG net |

80 drums(13.2mts)/20’FCL |

|

2 |

UN approved 830kg net tote |

20 totes(16.6MTS)/ 20’ FCL |

Guarantee Period: 12 Months.

Storage and transportation

Keep away from wet, fire and sunshine. To avoid decomposing, don't use for acid pump. When opening the bag, keep away from any warm object. Wear ocular and anti-toxin respirator to protect your skin, eye and no nasality. In case of contact, wash immediately with plenty of water for at least 15 minutes

Note:

This information is based on our present state of knowledge and is intended to provide general notes on our products and their uses. It should not therefore be construed as guaranteeing specific properties of the products described or their suitability for a particular application. Any existing industrial property rights must be observed. The quality of our products is guaranteed under our General Conditions of Sale.

Better mining reagents and solutions.innovative flotation reagents.

Creating Value for Environment, Society & Business

Related News

Tailings Management

Florrea partners with mineral processing companies to engineer tailings dewatering solutions that recover as much water as possible, giving you a more sustainable tailings disposal process while extending the life of your tailings storage facility and try to increase as much as possible the amount of a traditional tailings disposal solution – which ultimately helps to defer the heavy cost of building a new facility.

Zim container ship burns off coast of Canada

Zim container ship burns off coast of Canada

Florrea Dispersants

Florrea Dispersants